Maximize Your Batting Cage Lifespan: UV-Protected Nylon Nets with Inside-Out Technology

By netsdev | Jun 11,2025 | Batting Cage Netting

Our custom batting cage netting are constructed with high quality nylon netting, and utilize inside-out dyeing technology to achieve maximum breaking strength. The inside out technology color-treats each separate fiber within the rope with UV defense to extend the lifespan of your net. We also provide ceiling ropes that are spaced 6 to 8 feet apart and run in both directions to facilitate easy installation.

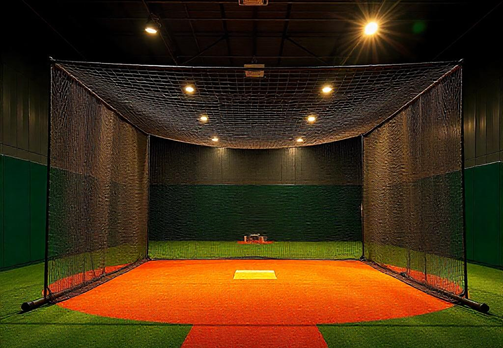

When securing custom batting cage netting to a cable system, you can position cables in either direction and they will inevitably cross with the overhead ceiling ropes. This also aids in reducing sag and preserves a more even, streamlined appearance in your enclosure. Enhance your cage with a sewn-in flap door for convenient entry, a lead-core rope, and an extra back drop net to prolong the lifespan of your enclosure.

Flexible Solution

Custom batting cage netting systems provide flexible solutions to cater for diverse requirements, encompassing baseball practice, player development, and site safeguarding. The correct mesh size is essential, with sizes varying from 3/4 inch to 4 inches based on the specific sport. The nylon netting has high quality and its breaking strength is maximized by being dyed using an inside-out process, which results in enhanced durability and performance. These cages offer a secure and effective space for practice, making them a significant improvement.

Benefits of Batting Cage

Crafted to perfectly fit your space and needs, this solution guarantees the best possible coverage and results.

Manufactured with high-grade materials such as nylon and constructed with an inside-out dyeing process to increase the product’s overall durability.

Custom batting cage netting creates secure barriers, thereby minimizing the risk of balls or objects getting out.

Designed for diverse uses, including batting cages, property protection, and sports training.

Custom sizes and finishes can enhance the visual appeal of your surroundings, resulting in a polished and professional appearance.

Precise sizing minimizes waste and guarantees that you only pay for the exact amount required.

Typically, the best materials for netting construction are high-quality nylon, polyester, and polyethylene.

Nylon boasts exceptional strength, durability, and resistance to wear, making it an excellent choice for demanding applications such as batting cages. When properly dyed, it provides excellent UV protection and retains its flexibility over time.

Polyester provides outstanding protection against UV rays and has good weather-resistance properties, which make it a good choice for use outside. It retains its shape and tension over a longer period due to its resistance to stretching and shrinking.

Polyethylene is known for its characteristics of being lightweight and resistant to moisture, chemicals, and ultraviolet rays. This type of netting is commonly used for lighter-duty or short-term applications, yet it maintains a satisfactory level of durability.

In high-impact sports environments, nylon material with UV-resistant dye inside-out technology is commonly chosen for its optimal lifespan and performance.

Effects

The mesh size has a substantial effect on netting performance, primarily by influencing the degree of containment, longevity, and security. Meshes with smaller openings (ranging from 3/4 inch to 1 inch) offer improved containment of smaller balls or objects, thereby lowering the likelihood of them escaping or being damaged. These are well-suited for baseball, softball, or golf uses where precise control is essential.

Mesh sizes of 2″ to 4″ allow for increased airflow, lower weight, and are suitable for bigger debris or less stringent containment requirements, however they may permit smaller items to pass through. Selecting a suitable mesh size is crucial for achieving an ideal equilibrium between transparency, durability, and performance tailored to your particular requirements.